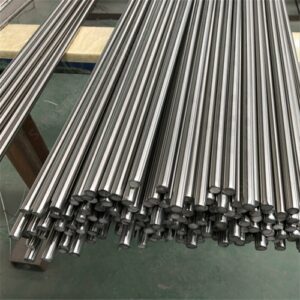

From Melting to Machining: The Manufacturing Process of Stainless Steel Round Bars

Stainless steel round bars are a popular choice in a variety of industries due to their strength, durability, and resistance to corrosion. These bars are used in construction, manufacturing, transportation, and many other applications. In this article,

Materials Used

Stainless steel round bars are made from a variety of materials, including austenitic, martensitic, and ferritic stainless steel.

Austenitic stainless steels are the most common and are known for their high strength, durability, and corrosion resistance.

Martensitic stainless steels are known for their hardness and are often used in applications that require a high level of wear resistance.

Ferritic stainless steels are less commonly used but are known for their corrosion resistance and high-temperature performance.

The Manufacturing Process

Stainless steel round bars are typically manufactured using one of two processes: hot rolling or cold drawing.

Hot rolling involves heating the stainless steel billet to a temperature above its recrystallization temperature and then rolling it into a round shape. The resulting bar is then cooled and cut to the desired length.

Cold drawing, on the other hand, involves pulling the stainless steel through a series of dies to create the desired shape and size.

Regardless of the manufacturing process used, there are several important steps involved in the production of stainless steel round bars.

First, the raw materials must be inspected and tested to ensure they meet the required specifications.

Next, the materials are heated to the appropriate temperature and formed into the desired shape. After the bars have been formed, they are cooled and inspected for defects. Finally, the bars are cut to the desired length and packaged for shipping.

Benefits of Stainless Steel Round Bars

- They are also highly resistant to heat and chemicals, making them ideal for use in a variety of harsh environments.

- Additionally, stainless steel round bars can be easily machined and welded, making them a versatile choice for a wide range of applications.

- In addition to their mechanical properties, stainless steel round bars are also highly attractive and can be finished in a variety of ways to create a polished, professional look.

- They are also highly recyclable, making them an environmentally friendly choice for companies looking to reduce their carbon footprint.

- Stainless steel round bars are an essential component in a variety of industries, from construction to manufacturing to transportation.

- By using high-quality materials and advanced manufacturing techniques, stainless steel round bar manufacturers can create bars that offer superior strength, durability, and corrosion resistance.

Whether you're looking for a strong, durable material for your next project or simply want to take advantage of the many benefits of stainless steel, stainless steel round bars are a versatile and reliable choice.

The manufacture of stainless steel round bars involves several steps:

- Material Selection: The first step is the selection of the appropriate raw materials. The type of stainless steel used depends on the specific application, and factors such as corrosion resistance, strength, and durability are taken into consideration.

- Melting: The selected raw materials are melted in a furnace, where they are heated to a high temperature until they become molten. The molten steel is then poured into a mold to form a billet.

- Hot Rolling: The billet is then heated to a temperature above its recrystallization temperature and passed through a series of rollers to form a long, thin bar. This process is called hot rolling, and it results in a round bar with a rough surface.

- Annealing: After hot rolling, the round bar is annealed, which involves heating it to a high temperature and then slowly cooling it down. This process relieves internal stresses in the metal and improves its ductility and toughness.

- Cold Drawing: The annealed round bar is then cold drawn through a series of dies to achieve the desired shape and size. This process results in a smooth surface finish and improves the dimensional accuracy of the bar.

- Finishing: The finished round bar is then polished, cut to the desired length, and inspected for defects such as cracks, voids, or surface imperfections.

- Packaging: The final step in the manufacturing process is packaging the finished round bars for shipping to customers.

Overall, stainless steel round bar manufacture involves careful selection of raw materials, precise control of the manufacturing process, and rigorous quality control to ensure that the final product meets the required specifications.

The manufacturing of stainless steel round bars is an important factor in the global market, as these bars are used in a wide range of industries and applications.

The demand for stainless steel round bars is driven by factors such as the growth of the construction industry, the expansion of the automotive and transportation sectors, and the increasing use of stainless steel in manufacturing processes.

- The global market for stainless steel round bars is highly competitive, with numerous manufacturers and suppliers operating in the industry. Factors such as product quality, price, and delivery times can all impact the market share of individual companies.

- The availability of raw materials, such as iron ore and nickel, can also have an impact on the price of stainless steel round bars and the competitiveness of manufacturers.

- Additionally, fluctuations in currency exchange rates and changes in trade policies can affect the global market for stainless steel round bars.

- Overall, the manufacture of stainless steel round bars plays an important role in the global economy, as these bars are used in a variety of industries and applications.

- The market for stainless steel round bars is influenced by a variety of factors, including supply and demand, raw material availability, and trade policies, and manufacturers must stay competitive and adapt to changing market conditions to remain successful.

- stainless steel round bar manufacturing is expected to grow at a steady rate over the next few years, driven by factors such as the increasing demand for stainless steel in the construction and automotive industries, as well as the growth of the manufacturing sector in developing countries.

According to a report by Market Research Future, the global market for stainless steel round bars was valued at USD 4.23 billion in 2017 and is projected to reach USD 5.61 billion by 2023, growing at a CAGR of 4.8% during the forecast period.

Asia-Pacific is expected to be the largest market for stainless steel round bars during this period, due to the growing demand for stainless steel in the construction and automotive industries in countries such as China, India, and Japan.

North America and Europe are also expected to experience steady growth in the market, driven by the expanding manufacturing sector.

The market is highly competitive, with numerous manufacturers and suppliers operating globally. Some of the key players in the market include ArcelorMittal, Nippon Steel & Sumitomo Metal Corporation, Acerinox S.A., ThyssenKrupp AG, and Sandvik AB.

Overall, the global market for stainless steel round bars is expected to continue growing in the coming years, driven by a variety of factors such as increasing demand in various industries and the expansion of manufacturing activities in emerging economies.

Stainless Steel Round Bar and SS Rod / Hex Bar Manufacturer

Stainless Steel Round Bars

Stainless Steel Round Bar, Stainless Steel Rod Manufacturer, ASTM A276 Stainless Steel Bar, Stainless Steel Half Round Bar, SS Solid Round Bar, SS Round Bar Size Chart, Hot Rolled Stainless Steel Round Bar, cold drawn stainless steel round bar, ASTM A479 Steel Round Bar, Stainless Steel Threaded Rod, Cold Rolled Stainless Steel Bar, ASTM A276 Rod, Stainless Steel Bar Price Per Kg, SS Round Bar Manufacturer in india, stainless steel round bar manufacturer in india, Stainless Steel Round Bar ASTM A276, Hot-rolled Stainless Steel Round Rod, 20mm Stainless Steel Round Bar, 8mm ss rod, 12mm Stainless Steel Round Bar, SS Round Bar Manufacturer.

stainless steel round bar

| rade | Stainless Steel Round Bar |

|---|---|

| Stainless Steel Square bar size | 4 to 100mm |

| Stainless Steel Hollow Bar | 32mm OD x 16mm ID to 250mm OD x 200mm ID) |

| Hot Rolled Steel Hex Bar size | 2-100mm A/F |

| Stainless Steel Angle bar size | 3mm*20mm*20mm~12mm*100mm*100mm |

| Stainless Steel Rectangles Size | 33 x 30mm to 295 x 1066mm |

| Hot Rolled Steel Flat bar size | Thickness: 2 -100mm |

| Width: 10 to 500mm | |

| Stainless Steel Channel Bar | 80 x 40mm to 150 x 75mm section; 5.0 to 6.0mm thickness |

| Stainless Steel Section | 3.0 to 12.0mm thickness |

| Hot Rolled Steel Round bar size | Diameter: 3-~800mm |

| Stainless Steel Billet Size | 1/2″ to 495mm Diameter |

| Stainless Steel Round Bar Standard Dimensions | Diameter / Height: Stainless Steel Rod and Bar Sizes : 0.5 inches / 0.625 inches / 0.75 inches / 0.875 inches / 1.0 inches / 1.125 inches / 1.25 inches / 1.375 inches / 1.5 inches / 1.75 inches / 2.0 inches / 2.25 inches / 2.5 inches / 2.75 inches / 3.0 inches / 3.25 inches / 3.5 inches / 3.75 inches / 4.0 inches / 4.25 inches / 4.5 inches / 5.0 inches / 5.25 inches / 5.5 inches / 6.0 inches / 7.0 inches / 8.0 inches / 9.0 inches. |

| Stainless Steel Surface | Bright, Hot Rolled Pickled, Cold Drawn, Sand Blasting Finished, Polished, Hairline |

| Stainless Steel Tolerance | H8, H9, H10, H11, H12, H13K9, K10, K11, K12 or as per clients’ requirements |

| Hot Rolled Steel Technique | Stainless Steel Hot Rolled, Cold Drawn, Cold Rolled, Forged Round Bar, Rod |

| Stainless Steel Condition | Hardened & tempered, annealed |

| Finish | Cold (bright) drawn, centreless ground, hot rolled, smooth turned, peeled, slit rolled edge, hot rolled annealed, Rough Turned, Bright, Polish, Grinding, Centreless Ground & Black |

| Form | Stainless Steel Round, Rod, T-Bar, Channel Bar, Precision Ground Bar, Flat Bar, Square Bar, Blocks, Round Rod, Rings, Hollow, Triangle, Rectangle, Hex (A/F), Threaded, Half Round Bar, Profiles, Billet, Ingot, I/H Bar, Forging etc. |

Customer Buy Stainless Steel Threaded Bar from SS Round Bar suppliers in Singapore, Canada, Houston, USA, UK, Indonesia, South Africa and Australia

Stainless Steel Sheet, Stainless Steel Coil